Do M63 (M65) series hydro-cooling miners and M64 series hydro-cooling miner use the same size quick connector?

The quick connector sizes used in M63 (M65) series hydro-cooling miners and M64 series hydro-cooling miners are different. The quick connector size used in M64 series hydro-cooling miners is slightly smaller, as shown in the figure below. The right side is the female quick connector of M63 series (M65 series), and the left side is the female quick connector of M63 series.

Figure 1

Will hydro-cooling miners come with quick connectors when they leave the factory?

The hydro-cooling miners come with male quick connectors when they leave the factory, but do not include feamale quick connectors. The male quick connectors are connected to miners, and the female quick connectors are connected to water pipes. If you need female quick connectors, you can purchase them yourself or contact us partsales@microbt.com.

Can you briefly introduce the size and model of quick connectors for M63 (M65) series hydro-cooling miners and M64 series hydro-cooling miners?

Series

Male Quick Connector Specification (stainless steel)

Female Quick Connector Specification (stainless steel)

Remarks

M63 (M65) Series

Model: AMG-M-M16X1.0-C6-08-S

(Alternative model: STL-BXG-GT-DN08)

Interface size: M16 x 1.0 mm screw thread

Interface sealing method: Sealing ring end face sealing

Color identification: Blue identification represents liquid inlet and red identification represents liquid outlet.

Model: AMG-F-G1/4”-08S

(Alternative model: STL-BXG-MT-DN08)

Interface size: G1/4 screw thread

Interface sealing method: Sealing ring end face sealing

Color identification: Blue identification represents liquid inlet and red identification represents liquid outlet.

The male quick connectors are connectors used for the original inlet and outlet of the miner. The red label is pasted onto the miner outlet, and the blue label is pasted onto the miner inlet.

The female quick connectors are compatible with the original liquid inlet connector and the original liquid outlet connector of the hydro-cooling miner. The liquid supply side and the liquid return side of the cabinet provided by you need to use such connectors to match the liquid inlet connector and the liquid outlet connector of the miner. The female quick connector labeled in red matches and connects with the male quick connector at the miner outlet, while the female quick connector labeled in blue matches and connects with the male quick connector at the miner inlet.

Note:

You should not replace this connector with the connectors of other specifications or other brands to match the original liquid inlet connector and the original liquid outlet of the miner.

For additional information about the M63 (M65) series hydro-cooling miners' quick connectors, please refer to the operation guide of the hydro-cooling miner.

M64 Series

Model: STL-BXG-GT-DN06

Interface size: G1/4 screw thread

Interface sealing method: Sealing ring end face sealing

Color identification: Blue identification represents liquid inlet and red identification represents liquid outlet.

Model: TL-BXG-MT-DN06

Interface size: G1/4 screw thread

Interface sealing method: Sealing ring end face sealing

Color identification: Blue identification represents liquid inlet and red identification represents liquid outlet.

Can you provide a brief introduction to the installation method of M63 (M65) series hydro-cooling miners' quick connectors?

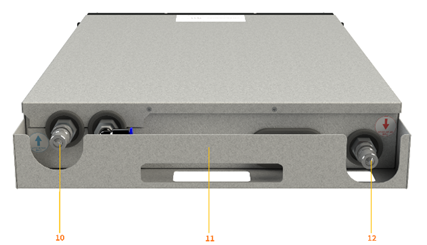

As shown in the figure, 10 and 12 are respectively a liquid inlet and a liquid outlet, both of them are male quick connectors. The material of the male quick connector comes in two types: aluminum alloy and stainless steel. The male connector is made of stainless steel by default when our miner leaves the factory.

Figure 2

It should be noted that female quick connectors are respectively compatible with an original liquid inlet connector and an original liquid outlet connector of the miner. Both the liquid supply side and the liquid return side of the cabinet provided by you needs to use such connectors to match the liquid inlet connector and the liquid outlet connector of the miner.

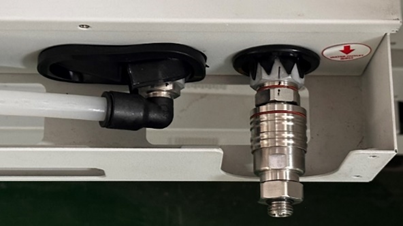

After your put the miner on the shelf, you need to connect female quick connectors with male quick connectors, and ensure that they are properly connected to each other. The following figures can give you a simple illustration.

Figure 3

What are differences between new and old quick connectors of M63 series hydro-cooling miners?

Old quick connectors (one set)

The old quick connectors and the new quick connectors are not compatible with each other. When purchasing and using them, it is necessary to distinguish between the two to prevent liquid leakage caused by cross use.

New quick connectors (one set)-aluminum alloy

New quick connectors (one set)- stainless steel

The new aluminum alloy quick connectors and the new stainless steel quick connectors are not compatible with each other. When purchasing and using them, it is necessary to distinguish between the two to prevent liquid leakage caused by cross use.

- 1WhatsMinerTool_Operation Guide

1K+

- 2WhatsMiner Hydro-Cooling Miner_Operation Guide

1K+

- 3WhatsMiner API_User's Manual

1K+

- 4WhatsMiner Air Cooling Miner_Operation Guide

1K+

- 5WhatsMiner Immersion Cooling Miner_Operation Guide

922

- 6How is the "Power Limit" feature used to optimize mining in WhatsMinerTool?

768

- 7 In WhatsMinerTool, there are two error codes about my miner, including 530 Slot 0 not found and 542 Slot 0 reading chip Id error. Could you guide me what should I do?

627

- 8 What are two most important indicators for a miner?

449

- 9How does Performance Mode affect mining operations in WhatsMinerTool?

436

- 10 What is Underclocking?

423